An innovation in the world of litter!

Made in Québec (Canada)

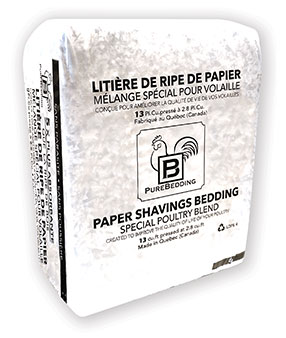

PURE BEDDING

paper shavings litter

A multitude of advantages for the poultry sector. Combines all the advantages of other types of litter available on the market, without the disadvantages!

Many advantages and savings for the poultry sector!

The list of advantages is impressive, both in terms of savings in production costs and benefits for the animal and biosecurity as well as manure recovery.

Pure Bedding litter combines all the advantages of other types of litter available on the market, without the disadvantages!

The information contained in this segment was collected from poultry breeders in Quebec who, through their observations, allowed the compilation of its many benefits and advantages. They recommend its use to all breeders.

Access the different sections to see the benefits:

Dust free!

Without moisture!

Manure 50% richer in nitrogen (N)

Food grade!

Soft and fluffy texture!

Very high absorbency.

Bag delivery!

Benefits of a dust-free paper shred!

We have received several testimonials from customers with asthma or dust allergies who no longer have symptoms when working inside their buildings since using our paper shavings.

The wood shavings contain a lot of dust and this is accentuated by the blowing on reception. Our paper shavings are dust free, you will notice that there is no dust in suspension when the bags are opened. The breeders have confirmed that they have completely eliminated the step of cleaning the walls and feeders because there is no dust deposit.

Since wood shavings contain a lot of dust, it is necessary to clean the filters of the tractor several times when leveling the received shavings. Following the use of our paper shavings, breeders have told us that the filters stay clean.

Circulation and ventilation raise the wood dust that settles on propane burners and these must be cleaned regularly to avoid the risk of fires. You no longer have to worry about this step with the paper shavings.

Benefits of a moisture-free paper shred!

Poultry farmers who use our paper shavings have noticed that the humidity sensors do not register any variation upon receipt of the shavings.

Since the shavings contain no moisture, you don’t have to heat them before the chicks arrive. As soon as you have finished leveling, the bed is ready to receive the chicks. You benefit from propane savings.

Since the shavings contain no moisture, you don’t have to heat them before the chicks arrive. As soon as you have finished leveling, the bed is ready to receive the chicks. This allows you to start a new batch faster and increases your annual yield per square foot.

Click here to see the document wet ripe, cold Novago chicks

As mentioned in the article ”Wet litter, main cause of pododermatitis” of the website: SUCCEED POULTRY The University of Wageningen in the Netherlands concludes that “the condition of the litter can have an impact from simple to doubles the gross margin of a batch of broiler chickens” Researchers induced the onset of pododermatitis by misting the bedding daily with wood shavings. The performance of the chickens is compared to that of a control group, housed in the same building on very neat bedding. The appearance of pododermatitis is obvious. At 21 days, the leg lesion score reached 110 points out of 200 for the batch on wet litter against 14 for the control batch. At 36 days, 99% of chickens show severe lesions against 2% for those on dry litter. At the end of the batch, chickens on wet litter are lighter and their consumption index is degraded. Wet bedding also has an impact on the recovery of carcasses at the slaughterhouse: cleanliness and lesions on the chest, burns on the tarsus and scratches.

Studies tend to show that with the use of our paper shavings, chickens reach the required weight in a shorter period, even when reducing part of the feed, i.e. 1 ton less for a batch of 20,000 broiler chickens.

Advantages of a Manure 50% richer in nitrogen (N) which composts much faster

A comparative analysis between a sample of poultry manure made from wood shavings and a sample of the same age made from paper shavings shows a “potentially available nitrogen level” of 50% higher for paper shavings

Digestion rate is the soil’s ability to take up nutrients from manure without becoming saturated. The breeder thus has the possibility of using a larger quantity of his available manure and reducing the use of much more expensive chemical fertilizers.

The use of his own manure in greater proportion and at a higher rate of available nitrogen (N) allows the breeder to considerably reduce his chemical fertilizer input.

Benefits of food grade paper shavings!

The papers we use are virgin and free of any harmful or toxic substance since they meet the standards for food grade applications. They are free of any parasites, mealworms or other insects. It is not newsprint or writing paper. This is a type of paper with great absorbency.

See article published by the Ontario Ministry of Agriculture, Food “The fight against the lesser mealworm in poultry houses” (Click on the link which directs to the article)

Download document: The control of lesser mealworm in poultry houses

Darkworms, flies and other harmful insects are a cause of mortality in chicks but it is also difficult to get rid of them and the costs related to their extermination are significant. Our food grade shavings eliminate the danger of being infested.

The papers we use are virgin and free of any harmful or toxic substance since they meet the standards for food grade applications. They are free of any parasites, mealworms or other insects. It is not newsprint or writing paper. This is a type of paper with great absorbency.

Ideal for birthplaces and post-surgery animals requiring a more sanitized bedding.

Pine and spruce are softwoods containing phenol, which irritates the respiratory tract. May cause long term problems. Small animals are more affected because they are in direct and constant contact with the shavings.

Benefits related to a soft and fluffy texture!

The soft texture of the material facilitates its levelling, even if the heap is of good size, the tractor does not encounter any resistance and passes easily through it, easily pushing the excess in front of the tines of the shavings spreader, reducing the time of leveling required for wood shavings. Its easily malleable texture allows a perfect leveling. Paper being less dense than wood shavings, you will never have water loss caused by an uneven level of shavings that causes pipettes to run

The paper being less dense than wood shavings, you will never have water loss caused by small bumps of uneven shavings that trigger the pipettes.

The paper being less dense than wood shavings, you will never have water loss caused by small bumps of uneven shavings that trigger the pipettes. This allows the water lines to be lowered to the desired level without fear of opening the pipettes and wetting the ripe.

Advantages linked to paper shavings with very high absorbency.

The types of paper used in the composition of our litter all have the property of being very absorbent. (Does not contain newsprint or writing paper). Liquids that come into contact with the shavings are immediately absorbed by it. A first advantage of this absorption is that the liquid will be entirely absorbed by the surface shavings, leaving the underside shavings completely dry. When removing the manure at a broiler breeder, they mention that only the 1st ¼ inch is soiled and the underside is like new. (A thickness of 1 ½” had previously been spread with the shavings spreader at the beginning of the batch and no shavings were added during the process.) Another advantage: The breeder notes an ease and increased speed of cleaning since the bottom shavings remain dry and do not stick to the floor.

Our paper shavings absorb a quantity of liquid 5 times greater than wood shavings and the absorption is instantaneous

Wood shavings manage to absorb only 20% of this quantity and absorption is slow, the liquid has time to run off before being completely absorbed and the quantity of soiled shavings is greater.

Flies are responsible for several diseases and infections and increase the cost of cleaning (droppings) on equipment and buildings See article published by the Ontario Ministry of Agriculture “Fight against the housefly in poultry farms” .

Download document: HOUSE FLY CONTROL IN POULTRY FARM Publication 849E – housefly

When cleaning the end of the batch of a broiler chicken farm, only the first ¼ inch was soiled, the litter underneath was still fresh. The breeder notes an increased speed and ease of cleaning since the shavings below remain dry and do not stick to the floor.

Benefits of bagged delivery!

With bagged delivery, the truck does not have to approach your buildings and higher risk areas and the delivery person does not have to enter your buildings.

Each delivery of shavings is a risk of contamination and the spread of viruses and diseases from other poultry houses. As the delivery of bagged paper shreds allows you to receive 3 times more shreds than the bulk blown wood, you thus reduce by 3 times the number of trucks circulating in your yard. An average 2-storey building with an area of 40’ x 200’ receives an average of 9 deliveries of bulk shavings per year, while it will need less than 3 trucks for bagged paper shavings.

(Trucks go from one farm to another and can spread viruses and diseases)

Unlike wood shavings, which compress very little, the soft texture of paper shavings makes it possible to compress many more cubic feet inside the bag.

The impressive number of advantages allows the breeder to save money in several ways. Increase in yields, reduction in mortality, savings in heating, savings in cleaning time and others, environment offering a better quality of life which is reflected in animal health. Savings on the purchase of fertilizer. (Explanation in more detail upon reading the entire document)

When receiving a truck of shavings in bulk, the breeder can hardly quantify the quantity of shavings received and cannot check the level of shavings in the truck. He must refer to the number of cubic feet listed on his delivery note. Receiving in bags allows you to know exactly the number of cubic feet received.

With bulk reception, it is difficult for the customer to respect an equal thickness of shavings for each batch because it depends on the quantity that has been loaded into the bulk trailer and how the delivery person will be able to separate it into equal batches. on each floor of the building. With bagged shavings, the customer always repeats the same quantity of bags for each batch, which ensures uniformity in the desired thickness.

*It is recommended to use the shavings spreader to spread and level the paper shavings because it has the ability to decompact and aerate the mixture in order to cover the maximum cubic feet and avoid waste.

The volume of a 53 foot bulk wood shavings trailer is 4000 cubic feet. A trailer of paper shreds contains 1056 bags of 13 cubic feet (13728 cu.ft.) That is the possibility of covering 3 times more surface area per delivery.

A truck of bagged paper shavings contains 3 times more shavings than the bulk truck, so you have the possibility of receiving only 1 delivery of bagged paper shavings for 3 deliveries of bulk wood shavings. This reduces the number of trucks on the road and the ecological footprint of all these trucks.

Bulk delivery leaves you with little time to receive your shavings. You must wait until the cleaning and sanitizing is complete and you must do this before the chicks are received, while allowing adequate drying time to reach the required humidity level. A truckload of bagged paper shavings contains the equivalent of 3 trucks of bulk wood shavings, which gives you the possibility of keeping the surplus in inventory and allowing you to start a new batch as soon as you are ready, without depending on the arrival time of the bulk truck. An inventory also allows you to reduce price variations and the risk of running out of litter (pandemic, closure of sawmills for an indefinite period, etc.)

The delivery of wood shavings in bulk leaves little margin of time for the reception of your shavings. You must wait until the cleaning and sanitizing is complete and you must do this before the chicks are received, while allowing adequate drying time to reach the required humidity level. With bagged paper shreds, you can have your shavings delivered at any time, you no longer have to wait for the end of a batch since you can now store your pallets of bags.

Bagged delivery reduces your risk in 2 ways:

By allowing you to keep an inventory and by offering the possibility of delivering at any time during your operations. You are no longer restricted by the short time between the end of a batch and the reception of the chicks and you are less dependent on the availability of deliveries from the supplier.

With bags still in inventory, you start your new batch when you’re ready. You are no longer dependent on the delivery date and time of the bulk truck.

Receiving a bulk wood truck requires about 3 hours of blowing.

With bagged paper shreds, just bring 2 pallets to the required floor, divide the total bags into 3 lots on the floor and open them with an Olfa type knife along the length to empty them quickly . Dividing the shavings into 3 batches makes it possible to level the floor more quickly. It is not necessary to place all the bags at regular intervals on the entire floor, 3 piles are sufficient since the shavings of paper are soft and easily malleable, the leveling tractor can therefore spread the shavings quickly and without difficulty. Following tests carried out with breeders, it only takes 3 people 20 minutes to divide the bags into 3 batches, open them and place the bags in the recycling bins. The bags we use are 100% recyclable.

AND DO NOT FORGET; you completely ELIMINATE the dust cleaning step.

13 cubic feet pressed to 2.8 cubic feet.

Dimensions: 24” x 18” x 11”